Capabilities

New Product Introduction

- BOM Analysis, Machine Programming Interface, and Process Documentation via Aegis NPI Software

- Business Management Systems utilizing Intuitive ERP

- Quick-Turn Prototype

- 3 to 5 day Process Time

- Dedicated NPI Cell

- Customer Design Feedback Mechanism

top

SMT Technologies

- Multiple High Speed Production Lines

- Single and Double Sided Boards

- Single-layer rugged/heavy construction

- Multi-layer complex high density fine pitched components including BGA, uBGA, connectors and 0201 placement

- Flex circuit technologies

- RoHS compliant manufacturing

top

Assembly Process Technologies

- Multiple board finishes including HASL, nickel-gold, and immersion tin

- PB Free, No Clean, RMA, and Water Soluble Chemistries

- Wave Solder w/Chip Wave

- Automated Thru-Hole Insertion; Radial, Axial, Dip

- Austin American Micro-Jet Aqueous Cleaning System

- Hand Assembly via Customized Work Cells and Progressive Flow Lines

- Electro-Mechanical Assembly with Dedicated Customer Product Cells

- Cable and Harness Interconnect from 8ga to 30ga Wire with Automated Laser and Mechanical Wire Stripping Terminations

- Selective Solder Automation Equipment

top

Test

- Development Services

- We can provide test station configuration to support manufacturing processes with in-circuit and functional testing to support customer designs.

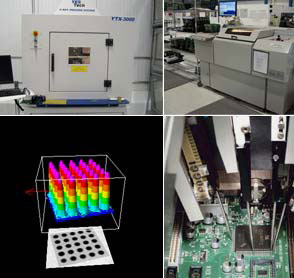

- Flying Probe Test

- Four independent test probes simultaneously apply the stimuli and perform the measurements needed to fully test a printed circuit board. Active and passive analog tests, signature analysis on each test point, boundary scan, and component presence and orientation and inspection are performed. This test, similar to in-circuit without the use of a fixture, is ideal for low-volume high-mix production and for first-piece and prototyping to prove out a customer design. This method of testing saves our customers time and money by improving throughput for new product introductions and eliminating the need for costly replacement fixtures when assemblies are redesigned.

- Functional Test

- Functionality of the final product can be tested to our customer's specifications using customer-furnished test equipment or special test equipment and specifications developed by Saunders Electronics.

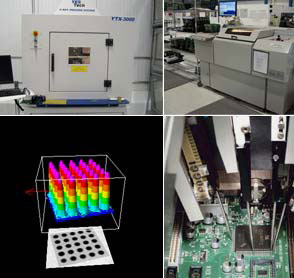

- X-Ray Imaging

- Quickly and automatically scans a printed circuit board assembly, analyzes the cross-sectional X-ray images and identifies the exact location and characteristics of solder joints, ensuring the quality of BGA placements and reducing costly and time consuming component removal and replacement.

top